LED Industrial Hemp Grow Lights - Opportunities for LED Plant Grow Lights

Before talking about cannabis lamps, it is necessary to understand the development history of the LED plant lighting industry and LED plant lighting companies in the past decade.

The research and development and application of LED solid light sources were first carried out by foreign countries. The cost of LED light sources was very high at the beginning of their development, so the price was naturally very high, which was not realistic for large-scale commercial civilian use. Japan was the first country to use LED light sources for plant cultivation research. Since then, NASA in the United States has used LEDs for lighting closed life support systems such as space bases. Since the 1980s, developed countries have begun feasibility studies on LED light sources as plant growth light sources. In the mid-1990s, LEDs were used in plant research facility cultivation. In the early 2000s, commercial LED plant lighting fixtures appeared. Around 2010, LED red and blue light plant lighting devices developed into the mainstream and were used in production fields such as plant factories.

Luxgrow can be regarded as one of the first Chinese companies to invest in the research and development and production of LED plant lighting products. At first, the lamps used for plant lighting were fluorescent tubes, which had the advantage of low price and obvious disadvantages of uncontrollable spectrum. LED red and blue light plant fill lights appeared around 2010, but the cost of LED is not affordable enough. The actual use of LED red and blue plant lights for fill lighting is generally in government demonstration projects, laboratories and overseas planting customers. Ordinary farmers are still not very receptive to LED plant fill lights.

LED red and blue plant lights use a ratio of red and blue lamp beads, mainly because a single LED chip cannot maturely "integrate" light of different wavelengths on the same chip. Since 2013, LED chips and packaging processes have become more and more mature, and full-spectrum LED plant growth lights have begun to appear on the market, but the market response has always been tepid. Due to the disproportionate cost of expensive lamps, electricity costs and crop output, as well as the limited level of agricultural modernization in my country, LED plant growth lights are less accepted in China. At the same time, LED plant lights are also used in modern vertical farms for vegetable and fruit planting.

The turning point appeared in 2018-2020. The industrial hemp market was gradually liberalized in North America, and some other countries also put the question of whether to liberalize industrial hemp cultivation on the agenda. Industrial hemp, a crop with high economic added value, "endowed" plant growth lamps with new life. Industrial hemp planting lamps began to become popular, and many domestic lighting companies entered the market.

The TPO company is FIuence, which was acquired by OSRAM. Through repeated experiments and comparisons, it has found a lamp bead ratio scheme that is most effective for cannabis cultivation - OSRAM's red (660nm) and Samsung's high-efficiency white (301B). Gradually, the market has recognized this spectrum scheme, and ordinary lighting companies that have entered the market believe that claiming to use such a scheme is a cannabis lamp. Is this actually the case?

Compared with some plant lighting companies that have entered the market in the past two years, whose cannabis lamp products are mainly "selling lamp beads", Luxgrow is doing another Chinese domestic solution in the environment where the market is chasing OSRAM + Samsung lamp beads - more advantageous prices, more than half a year of planting trials, benchmarked cost-effectiveness, and high-quality product technology

Compared with traditional plant planting supplementary lighting solutions, the advantages of LED are obvious. Industrial hemp planting is bound to carry LED plant growth lights for a while, but when the heat fades, LED plant lighting will still fall into the hands of down-to-earth companies.

Luxgrow is developed by photology engineers and more than 13 years R & D engineers team in led lights

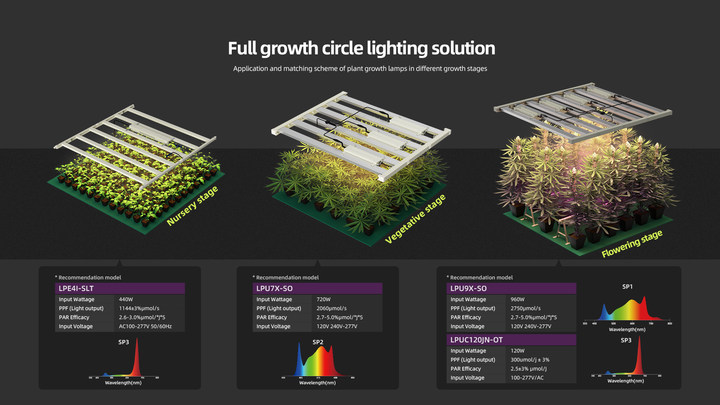

As a professional and rich experience grow light designer and manufacturer for indoor greenhouse farms ; Luxgrow really knows offer the exclusive customized layout service is very necessary and cost-efficient.

We offer free exclusive customized layout service for customers , not only in the lighting configuration help,but also help you know the budget